News & Events

OPTICS POLISHING ABRASIVES CAN BE MIXED BY USER TO DESIRED RATIO

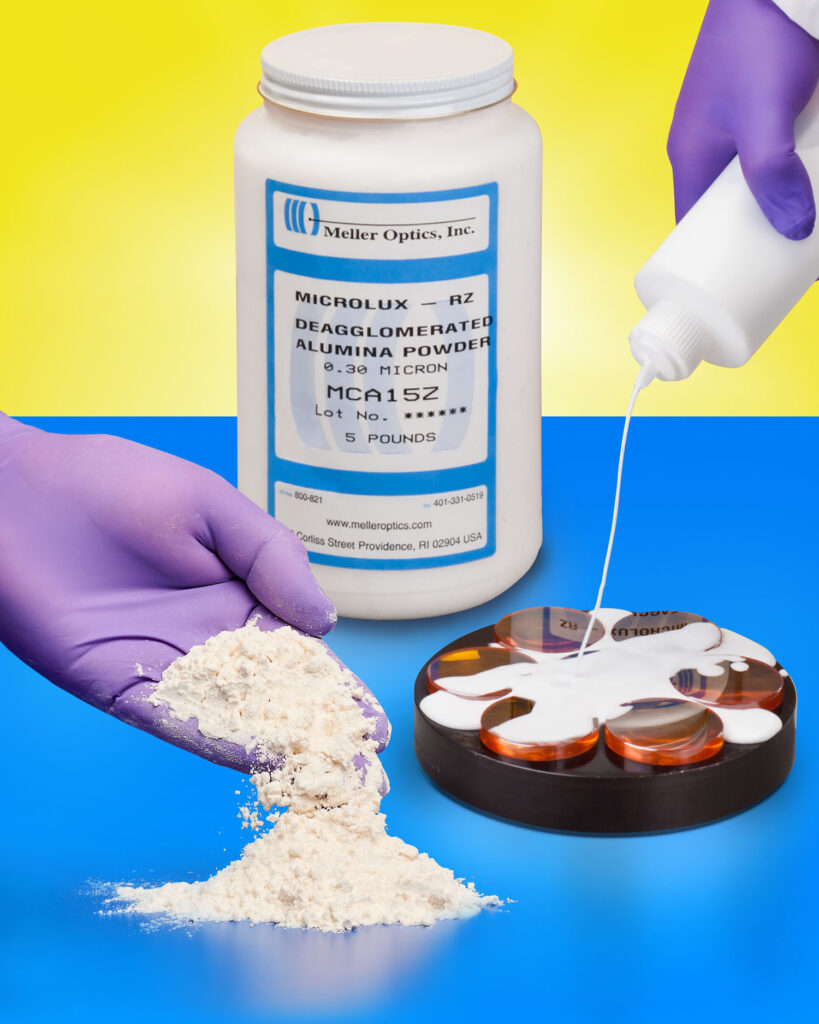

A line of high purity calcined alumina polishing powders offered in two grades and seven particle sizes that can be mixed to match their optical material has been introduced by Meller Optics, Inc. of Providence, RI.

Meller Microlux Alumina Powders are offered in two ultrapure grades and feature seven particle sizes from 0.05 to 3.0 microns for application directly to optics on mounted on spot blocks. Suitable for grinding, lapping, and polishing hard and soft materials including zinc selenide, germanium, silicon, and stainless steels, these petroleum-free abrasives can be mixed by the user with de-ionized water to achieve any ratio.

Capable of producing finishes to 10-5 scratch-dig, Meller Microlux-R Alumina Powders have large agglomerated particles for aggressive grinding and lapping that break down under pressure for final polishing and are 99.98% pure. For the ultra-fine polishing of semisoft crystalline and composite materials, Microlux-RZ is 99.99% pure with de-agglomerated powders and controlled particle sizes.

Meller Microlux Alumina Powders are priced depending upon quantity. Samples and price quotations are available upon request.