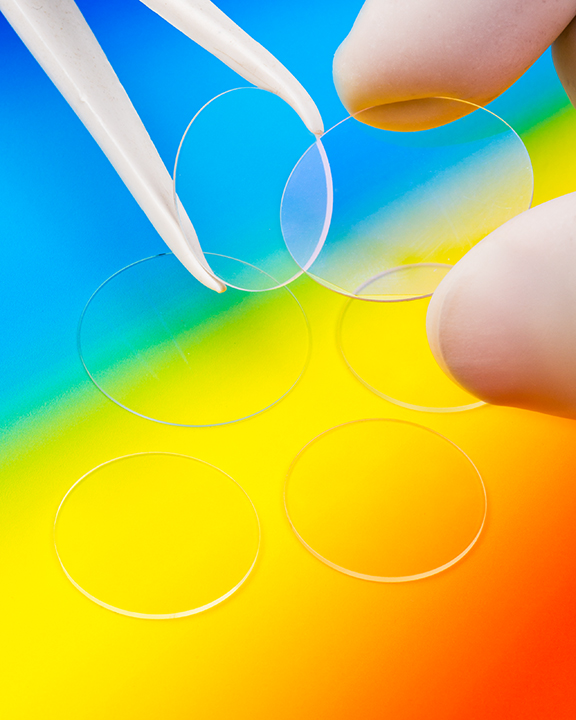

Sapphire Windows

Meller Sapphire Windows feature Mohs 9 hardness (second only to diamond) to enable them to withstand fast moving dirt, sand, and saltwater, and can be custom fabricated to match precise design requirements. Ideal for providing front surface protection, they are available with multi-spectral antireflective coatings that can meet salt fog requirements.

Various Configurations can be custom fabricated and coated to customer requirements and specifications.

Request a quote