News & Events

CUSTOM LIDAR OPTICS MATCH TRANSMISSION REQUIREMENTS

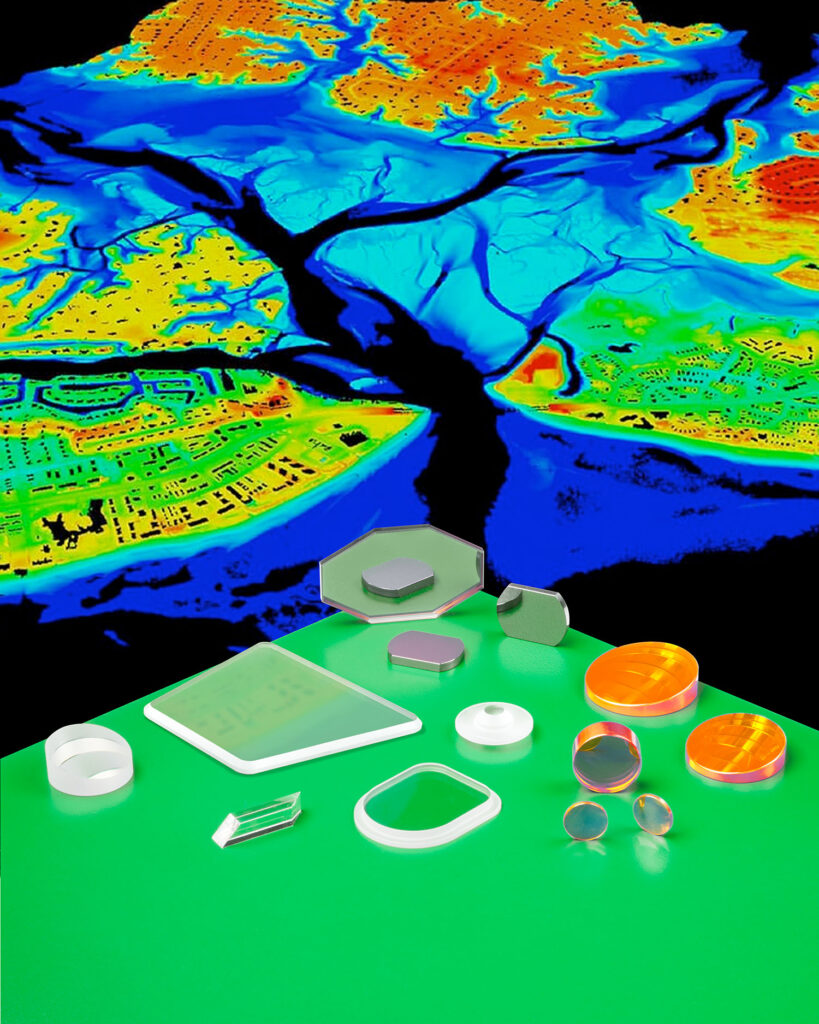

A wide range of LIDAR (light detection and ranging) optics that can be custom fabricated to match specific military and commercial application requirements has been introduced by Meller Optics, Inc. of Providence, RI.

Meller LIDAR Optics can be made from germanium, sapphire, silicon, UV glass, zinc selenide, zinc sulfide, and other materials to match specific transmission requirements from the UV to IR. Conforming to ISO-10110 specifications, they can be fabricated to OEM requirements as lenses, windows, and mirrors in plano-concave, concave, and meniscus shapes and as prisms.

Manufactured in sizes from 0.25” to 4” O.D. or diagonal with ±0.005” tolerance and thickness to ±0.002”, Meller LIDAR Optics are available with or without anti-reflective coatings. Special features can include steps, and holes for mounting and surface finishes of 10 waves to 1/10th wave flatness and 10-5 to 80-50 scratch-dig can be provided.

Meller LIDAR Optics are priced according to material, configuration, and quantity. The firm is ITAR registered.